|

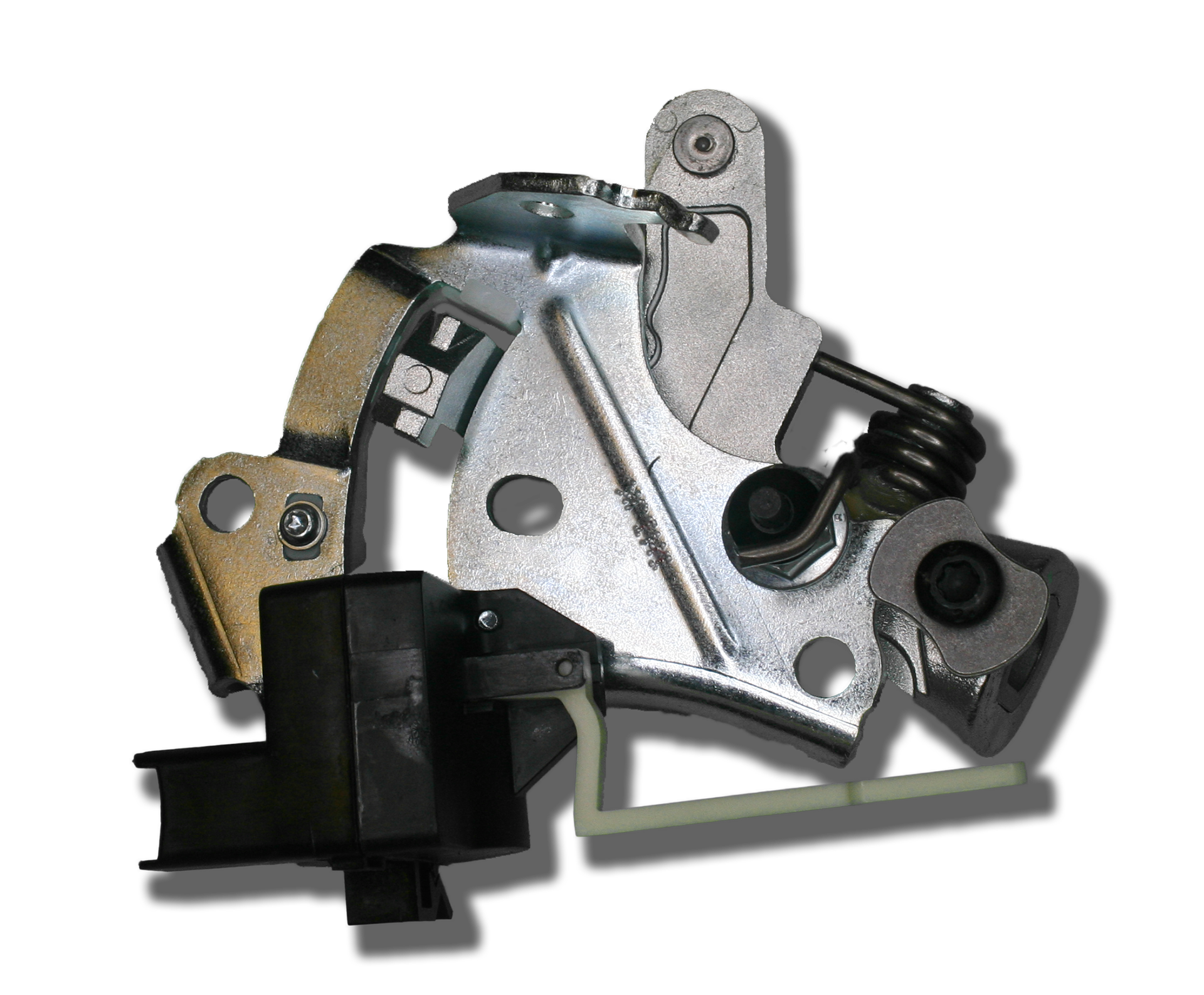

Over the years the Admiral product development team has taken on challenges and developed solutions that enhanced safety, reduced cost, reduced timing and increased part reliability. |

|

How We Have Helped

Example 1:

Redesigned a Full-Size pickup Truck tilt mechanism

Benefits Achieved:

Improved driver ergonomics

Reduced number of parts

The customer saved $36M

Example 2:

Designed, quoted, and awarded a more efficient shift mechanism for a Full-Size Pickup Truck

Benefits Achieved:

Improved driver ergonomics.

Reduced number of parts

Improved Quality

Reduced Assembly Time

Reduced Part Price

Example 3:

Redesigned a Full-Size Pickup Truck shift mechanism after award

Benefits Achieved:

Improved Part Reliability

Improve Safety

Reduce Part Price

|

|

Engineering Tools Our process also includes the use of Finite Element Analysis and 3D printing to validate the design prior to creating prototypes and completing validation in our laboratory.

|

Comprehensive Test and Validation Capabilities

|

|

Admiral Tool continually invests in equipment to insure inspection and test accuracy.

-Full DV/PV Testing Capability |